Having the ability to split our services individually, or combine as part of longer-term development needs, Medical Design Group offer flexibility throughout the design & development process. Medical Design Group offers modular services that can be tailored to clients needs or combined for comprehensive, long-term developments. Our flexibility ensures a customised design & development process to meet client needs.

Complete Product Design

We offer a full spectrum service for medical device design & development, our team is able to support an entire development or particular aspects as required.

We offer modular services that can be tailored to clients needs or combined for comprehensive, long-term developments.

Our flexibility ensures a customised design & development process to meet client needs.

Creative Workshops

Creative workshops at Medical Design Group serve as vessels for innovation. In these collaborative sessions, our cross-functional teams (comprising designers, engineers, and medical experts) converge to explore novel ideas. We sketch, prototype, and challenge assumptions, pushing the boundaries of what’s possible.

These workshops breathe life into groundbreaking concepts, ensuring that our design solutions are not only functional but visionary.

Outcome – Refined design solution(s) blending creativity with feasibility.

Technical Feasibility Reviews

Creative workshops spark ideas, while feasibility reviews assess practicality. Both ensure alignment with business goals.

Our evaluation process assesses the practicality and viability of an idea or design concept from a technical perspective.

Identifying & understanding the key development risks is a valuable undertaking ahead of any product development; our team of experts can help identify all center-stage activities of a development ahead of heavy investments.

Outcome – Showcasing all risks identified to ensure our clients are informed ahead of a development.

Medical Device Strategies

Strategic planning considers market entry, competitive landscape, and regulatory pathways. It’s about positioning for success.

Working with our clients we piece together strategies that work and will enable a clear pathway to product realisation.

Outcome – A roadmap that navigates both clinical needs and market dynamics.

Usability & Human Factors Engineering

Usability & Human Factors Engineering

At the heart of our product design and development process lies Usability & Human Factors Engineering.

At the heart of our product design and development process lies Usability & Human Factors Engineering.

We ensure that all products developed through our internal processes comply with key standards such as IEC 62366-1, ISO 14971, and guidance from MHRA & FDA.

Understanding the needs of a user group is crucial in generating fundamental and meaningful user requirements for development; here at Medical Design Group, we integrate Risk Management with Human Factors and Usability Engineering to adopt a user-centred approach in designing and developing medical devices. This approach guarantees that the products we create can be used safely and efficiently under real-world conditions.

Medical Design Group offer a full solution to Usability & Human Factors Engineering and are positioned well to fast-track iterative designs based upon user feedback.

Outcome – Enhanced user experience & market acceptance.

Navigating the Regulatory Landscape

- Regulatory Strategies

- Full Product Compliance

- Technical File Management

- Regulatory Roadmaps

From navigating the MDR to supporting 510(k) applications with the FDA, the experienced team at Medical Design Group are here to help provide guidance and support with planning your regulatory pathway through to compliance.

Risk Management

Creating the safest possible product (& system) is essential when designing a Medical Device.

Having extensive experience with complex medical device products & systems (including SaMD), the team at Medical Design Group Ltd have created a Risk Management Process that is apparent throughout the full life cycle of a development.

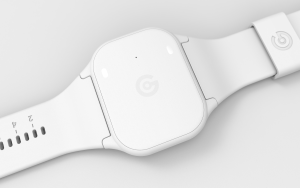

Packaging & Labelling Design

From smart wearable device packaging that lasts several years to single use, sterile pouches, we’ve designed them all.

Having trusted partner manufacturers offering an assortment of materials and technology alike we can help our clients reduce the CO2 impacts of their development whilst keeping costs low.

- Cost effective solutions

- Global supply chain

- Fantastic out-of-box experiences

- Adherence to regulatory requirements

- Semi & Automated packaging

- UDI Barcoding

Volume Manufacture

Gearing up for volume manufacture is at the forefront of our minds when designing products; the experienced team at Medical Design Group have helped multiple clients with our understanding of Design for Manufacture & Assembly (DfMA), and our right first-time ethos.

We ensure quality assurance through our trusted network of manufactures with Technical Quality Agreements, these lay out terms and conditions for each component that is manufactured ensuring conforming products are provided.

- Globally established manufacturer network

- Low & High-Volume manufacturing processes

- Assembly (semi-robotic and manual builds)

- Distribution network (EU & US)

Product Launch Support

A successful launch drives revenue.

Medical Design Group can support full product rollout, provide marketing & exhibition materials in addition to supporting training schemes for new users.

We regularly conduct post market surveillance for our clients on their devices and feed insights into new & existing technical developments.

Outcome – A well-executed launch that captures market attention.

Get in touch

Don’t hesitate to reach out, we look forward to understanding your project requirements and seeing how we can help!

Medical Design Group Ltd

Unit 3, Castleton Court, Fortran Road, St Mellons, Cardiff, CF30LT

info@medical-design-group.com

+44 (0) 29 22 809 911

Company Number: 14452119

VAT Number: GB441147913

© Copyright 2025 Medical Design Group Ltd. All rights reserved.